A rupture disc, also known as a pressure safety disc, burst disc, bursting

disc,

or

burst diaphragm, is a non-reclosing type of pressure relieving safety device that,

in

most

cases, protects a pressure vessel, equipment or system from over-pressurization or

potentially damaging vacuum conditions.

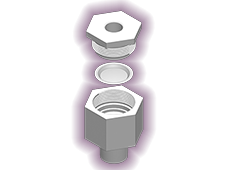

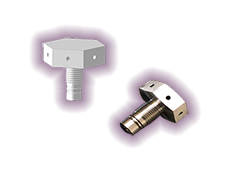

A rupture disc is a sacrificial, non-reclosing pressure relief device actuated by inlet static pressure and designed to function by the bursting of a pressure-containing disc. The disc may be made of metal or carbon graphite and is housed in a suitable holder. Rupture discs are designed ensuring cost-effectiveness and accuracy for usage in the most challenging industrial pressure relief applications.

What is Rupture Disc?

A rupture disc is a device designed to function by the bursting of a pressure-retaining disc. When the process reaches the bursting pressure of the disc, the disc ruptures and releases the pressure. Rupture discs can be installed alone or in combination with other types of devices.

The following variants of rupture discs are manufactured at Varem Technical Solutions:

Rupture Disc Manufacturer In India

Varem Technical Solutions is a popular rupture disc manufacturer in India that supplies diverse models of rupture discs to prevent potentially hazardous explosions caused by high-pressure or vacuum conditions. The device bursts whenever the pressure exceeds the safety mark and releases the excess pressure outside the system.

The Purpose Of Using A Rupture Disc

Accurate pressure safety solutions must be implemented since the possibility of a sudden and dangerous explosion is extremely high, particularly in industries and manufacturing facilities. The purpose and role of a rupture disc, the pressure safety device used in engineering-based industries, is to prevent explosions caused due to excess pressure. By using the pressure relief principle, the device ruptures to balance or regulate the high-pressure condition inside a vessel or a closed system. Varem Technical Solutions, the popular rupture disc supplier supplies rupture discs complying with regulatory and industrial standards.

The explosion relief panels are pressure safety devices designed to open and release the excess or high pressure generated inside a vessel or a closed system. By choosing reliable explosion vents and relief panels among the diverse versions such as single-layered and multi-layered, the excess pressure can be released to prevent dangerous explosions.

The Types Of Rupture Discs For Pressure Relief

Rupture Discs are categorized into different types based on their functionality and operating principles. Forward-acting rupture discs, Reverse buckling rupture discs, and Custom rupture discs are the rupture disc models manufactured at Varem Technology Solutions. These models are excellent in terms of accuracy, reliability, and operating performance.

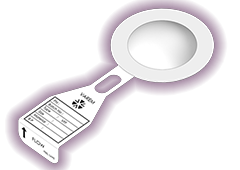

Forward-Acting Rupture Disc

Forward-acting rupture disc is a type of rupture disc in which the concave side of the dome faces away from the process media. The loads are applied to the concave side of the disk. The disc operates whenever the weakest portion of the dome exceeds the tensile strength.

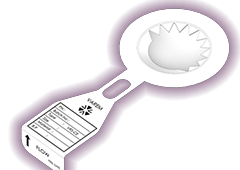

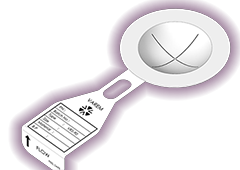

Reverse Buckling Rupture Discs

Reverse buckling rupture discs are designed in such a way that the convex side of the dome faces toward the process media. Whenever the pressure exceeds the threshold limit, the disc bursts to release the excess pressure. The reverse-buckling rupture discs are compression-loaded and require less force to burst when compared with the forward-acting rupture disc.

By considering the safety and operating requirements, rupture discs can be chosen among the diverse categories and used in a wide range of industries such as petrochemical, aerospace, aviation, and defense. Among the Rupture Disc suppliers and manufacturers, Varem Technical Solutions stands ahead in the market when it comes to the quality and operating performance of the safety devices manufactured.

Types of Rupture Discs

Benefits

Safety from pressure fluctuations.

Can operate under vacuum

Easy to install

Monitored sensor support

Low cost maintenance

FAQ

What is a rupture disc used for?

A rupture disc is a pressure relief safety device that is used to evoke a safety mechanism under extreme pressure situations that will safeguard a facility and its valuable assets from destructive damages.

What is the working technique of a rupture disc?

A rupture disc is designed in such a way that enables the breaking mechanism to come into effect in order to offset the extremely high or low pressure situations. A rupture disc monitors the pressure condition around it and when it breaches the set level, the disc breaks in order to subside the damage levels that would be an effect due to the created pressure condition.

Will rupture discs work under vacuum?

Well, rupture discs can work under vacuum provided there is a vacuum support system is in place. However, reverse buckling discs prove to be an exception here as they tolerate full vacuum without any support.

Is a rupture disc also a vacuum Breaker?

A rupture disc can definitely be used as a vacuum breaker but provided it is fitted in the right position which means fitting it in a reverse or an inverted position will enable it to function accordingly by monitoring the difference in pressure levels.

What is a reverse buckling rupture disc?